ball mill grinding balls europe

2022-01-24T05:01:55+00:00

Grinding Media Grinding Balls Steel Grinding Balls for Mining

2023年10月20日 MANUFACTURING grinding balls of European quality About company «Energosteel» is a leader in Ukraine MANUFACTURING grinding balls of European Our company is a leading manufacturer of rubber spare parts, rubber spare details and rubber linings for the oregrinding mills We produce more than thirty different types of Suppliers grinding balls EuropagesBall Mill Overview Most people are familiar with the type of vertically aligned milling machines with revolving blades This type of traditional model is often used by manufacturers to reform objects A ball mill is another Grinding ball Magotteaux

Ball Mill RETSCH powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications Cooling, heating cryogenic grindingThe use of ball milling as a defibrillation method after a series of pretreatments of raw materials was also described by the group of Elkoun, who reported the extraction of CNFs and s from carrot pulp by ball Ball milling: a green technology for the preparation SPI Supplies Brand Agate Ball Mill Grinder Balls, 40 mm Diameter, Pack of 5 Balls Item 05224AB $18360Agate Ball Mill Grinder Balls SPI Supplies

TOYO GRINDING BALL Co, Ltd

2019年5月14日 Buy Back Used Balls; Contact Us; Contact Us; 0364578080; NEWS 2019/05/14 Our website is renewed more Employment Mill Auditing; Ball Sorting Machine; Buy Back Used Balls; TOYO GRINDING BALL Co, Ltd 4F, 2310, Shinjuku, Shinjukuku, Tokyo JAPAN TEL2023年10月20日 Despite its short history, Energosteel managed to become a manufacturer of quality grinding media for ball mills, as well to keep its position on both the domestic and overseas markets The operational properties of steel balls produced by Energosteel allow to significantly reduce the consumption of grinding balls and power, to increase Grinding Media Grinding Balls Steel Grinding Balls for MiningA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles Ball mill Wikipedia

Grinding Media Balls Market Size, Share, Growth Analysis, By

Global grinding media balls market in Europe is primarily driven by increasing demand for power plants, cement production, Asia Pacific holds the largest market, with a share of about 60%, followed by North America and Europe Grinding media ball mills in the cement industry are in high demandA 42ft SAG mill was designed and built for Minas Congas mine in Peru, but never installed “The rise from 34 to 40ftdia SAG mills was quick, but then stalled,” Filidore explained “Today, we’re seeing a lot of 28ft ball mills Last month, we sold six 28ft ball mills and six 40ft SAG millsGetting the Most From Milling Operations E MJ2021年12月27日 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the Effect of Grinding Media Size on Ferronickel Slag Ball Milling

ball mill thyssenkrupp Polysius

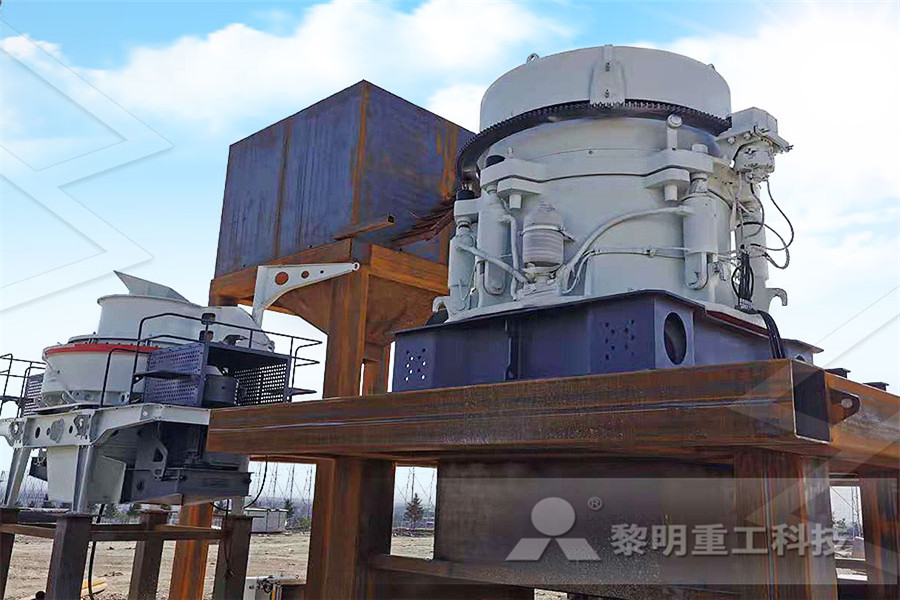

Ball Mill The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball 2022年8月15日 Grinding Ball Europe is product quality is very stable, with small personality differences, In this way, in the beneficiation and grinding operations, even in the semiautogenous mill, the grinding balls are guaranteed to have a strong pointtopoint impact on the ore, so that the grinding balls are not broken and round, Grinding Ball Europe AGICO CEMENTA feature of ball mills is their high specific energy consumption A mill filled with balls, working idle, consumes approximately as much energy as at fullscale capacity, that is, during the grinding of material Therefore, it is most disadvantageous to use a ball mill at less than full capacityBall Mill an overview ScienceDirect Topics

Grinding Balls Rods 911 Metallurgist

2016年10月20日 Grinding Balls Steel balls ranging from ¾ to 5 in in diameter are used Rods range from 1½ to 4 in in diameter and should be 3 to 4 in shorter than the inside mill length Tube mills are usually fed balls smaller than 2 in, whereas 4 or 5in balls are more commonly used for ballmill grindingIn a planetary ball mill, each jar represents a “planet” This planet is located on a circular platform, the socalled sun wheel When the sun wheel turns, the jar rotates around its own axis, but in the opposite direction Thus, centrifugal and Coriolis forces are activated, leading to a rapid acceleration of the grinding ballsPlanetary Ball Mills RETSCH fine grinding of materialsSteel Grinding Balls To buy at a profit in SPE «TechEnergoProm» LLC On our website, you will find hundreds of metal product names with the steel grinding balls, which can be bought in necessary quantities with consideration for specifics of use as well as the grinding bodies for ball mills of some varieties, among themSteel Grinding Balls in USA and Europe TechEnergoProm

Grinding Media in Ball MillsA Review Preprints

2023年4月24日 Review Grinding Media in Ball MillsA Review Nyasha Matsanga 1,*, Willie Nheta 1 and Ngonidzashe Chimwani 2 1 Mineral Processing and Technology Research Centre, Department of Metallurgy, University of Johannesburg, POBOX 17011, Doornfontein 2028, South Africa; 2 Department of Mining Engineering, 2021年12月11日 The breakage and liberation of minerals are the key to fluidized mining for minerals In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier to determine the breakage behavior of ores and the production capacity of the mill When ground products present a much coarse or much The Effect of Grinding Media on Mineral Breakage Properties of then to the grinding medium These ball mills are the most widely used in the eld of cellulose and they can be further divided into three groups: tumbler ball mills, vibratory mills and planetary mills (Fig 2b) A tumbler mill consists of a cylinder partially lled with steel balls rotating about its longitudinalaxisInthistypeofinstrument Ball milling: a green technology for the preparation and

Ceramic Grinding and Milling Media Zircoa

1050 Radius end cylinder, banded satellite sphere engineered for grinding and milling of zircon, zirconia, barium titanate, food stuffs, pharmaceuticals, electronic ceramics in vibratory, ball, jar and attritor mills Zircoa grinding media is nonporous, nonconductive, nonmagnetic, chemically inert, chipresistant and extremely hard2017年4月28日 Open Circuit Grinding The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit The conditions were as follows: Feed rate, variable from 3 to 18 T per hr Ball load, 28,000 lb of 5, 4, 3, and 2½in balls Speed, 197 rpmBall Mill Grinding Theory Crushing Motion/Action InsideLM PBM4000 Planetary Ball Mill LAARMANN’s Planetary Ball Mill has, unlike other similar machines, four positions where up to eight 500ml grinding jars can be placed Each grinding jar needs to be filled with a LM PBM4000 Planetary Ball Mill Laarmann Group BV

Ball Mill Suppliers and Manufacturers go4WorldBusiness

Forged grinding steel balls used in ball mill for mining industries: Diameter: 20mm, 25mm, 30mm, 40mm 50mm 60mm 70mm 80mm 90mm Hardness: HRC6065(Surface and Volumetric) Characteristics: High hardness, good wear resistance, no breakageThere are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]Grinding in Ball Mills: Modeling and Process Control Sciendo8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

Ball Mills 911 Metallurgist

2017年2月13日 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volumeMSE Supplies provides quality, durable, and highperformance milling media Milling balls made of steel and ceramic are our most popular materials If you have questions regarding MSE Supplies milling media, please request a quote, contact us online, or call us at (520)7896673 today Our inhouse experts are ready to help you select the best Milling Balls Grinding Media Grinding Balls MSE SuppliesThe Laboratory Ball Mill is primarily designed for grinding pigments and cement The material is ground at a specific speed for a specific period using a specific quantity of grinding steel balls The size range of balls provided to support the tests is from 12540mm The size of ball varies with the requirement of the tests and complied TO441 MODEL of Laboratory Ball Mill from Tinius Olsen

Energy efficient cement ball mill from

Key benefits High reliability – over a century of experience with 4000+ ball mills installed globally Large throughflow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height Increased effective grinding area with Stanex diaphragm designA pharmaceutical ball mill is a type of grinder used to grind and blend materials while manufacturing various dosage forms The size reduction is done by impact as the balls drop from near the top of the shell Ball mills are used primarily for singlestage fine grinding, regrinding, and as the second stage in twostage grinding circuitsBall Mill Principle, Construction, Working, and More Soln PharmaLab ball mills – these can accommodate zirconia balls ranging between 10mm15mm; Roll ball mills; Planetary ball mills; Each of these machines has different parts that make one better suited than the other Therefore, Zirconia ball, Top Quality Grinding media and milling

Grinding in Ball Mills: Modeling and Process Control Sciendo

2013年3月15日 Experimental Investigation on a Grinding Rate Constant of Solid Materials by a Ball Mill Effect of Ball Diameter and Feed Size Powder Technology, Vol 143/144 , 2004, 196203 101016/jpowtec200404014 in Google Scholar2021年7月12日 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure Some of them use the standard mill, while others are based on a nonstandard mill or computation techniques Therefore, papers targeting to propose a better A Review of Alternative Procedures to the Bond Ball Mill MDPI2022年4月20日 Surface hardness of our forged steel grinding balls ranges between 5862 HRC with volumetric hardness ranging between 5562 HRC Our steel balls for use in mineral processing SAG mill and ball mill operations bring about minimum wear and breakage rates Several factors affect forged grinding balls’ mechanical propertiesForged Steel Grinding Balls Alpha Grinding Media

Sino Grinding About

Capacity: 100,000 metric tonnes of rollforged balls 50,000 metric tonnes of hammerforged balls per annum Products: SAG BALL mill balls Product Diameter Range: 20 to 160 mm Location: Sichuan SGI leads the market with technical design and quality control of SAG and ball mill grinding media productionZirconium Oxide Grinding Balls Highly polished YSZ (Yttrium stabilized ZrO 2) zirconium oxide grinding balls for planetary and high energy ball mills Grinding jar ball configurationAcross International Zirconium Oxide Grinding BallsDuralox 92W Ceramic ball mill lining bricks and grinding media have been developed by Jyoti Ceramic after many years of R D with the intention of It works on the same principle as batch type ball mills Recommended grinding media : Balls of Ø 125mm to Eastern Europe Russia Jyoti Ceramic Cz sro, Na Okrouhliku 1781 Ceramic Ball Mill Lining Bricks Grinding Media Duralox® 92W

Effect of ball and feed particle size distribution on the milling

2018年6月1日 During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig 1A chemical reaction on the other hand can consist of say reactant ‘A’ forming intermediate product ‘B’ then proceeding to final product ‘C’ or a competing reactant ‘A’ A wide variety of steel balls options are available to you, such as steel, stainless steel There are 5 steel balls suppliers, mainly located in Africa The top supplying country is South Africa, which supply of steel balls respectively Steel balls products are most popular in Domestic Market, Mid East, and Western Europesteel balls for sale south africa KOOKSBall mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications Cooling, heating cryogenic grindingBall Mill RETSCH powerful grinding and homogenization

Ball milling: a green technology for the preparation

The use of ball milling as a defibrillation method after a series of pretreatments of raw materials was also described by the group of Elkoun, who reported the extraction of CNFs and s from carrot pulp by ball SPI Supplies Brand Agate Ball Mill Grinder Balls, 40 mm Diameter, Pack of 5 Balls Item 05224AB $18360Agate Ball Mill Grinder Balls SPI Supplies2019年5月14日 Buy Back Used Balls; Contact Us; Contact Us; 0364578080; NEWS 2019/05/14 Our website is renewed more Employment Mill Auditing; Ball Sorting Machine; Buy Back Used Balls; TOYO GRINDING BALL Co, Ltd 4F, 2310, Shinjuku, Shinjukuku, Tokyo JAPAN TELTOYO GRINDING BALL Co, Ltd

Grinding Media Grinding Balls Steel Grinding Balls for Mining

2023年10月20日 Despite its short history, Energosteel managed to become a manufacturer of quality grinding media for ball mills, as well to keep its position on both the domestic and overseas markets The operational properties of steel balls produced by Energosteel allow to significantly reduce the consumption of grinding balls and power, to increase A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles Ball mill WikipediaGlobal grinding media balls market in Europe is primarily driven by increasing demand for power plants, cement production, Asia Pacific holds the largest market, with a share of about 60%, followed by North America and Europe Grinding media ball mills in the cement industry are in high demandGrinding Media Balls Market Size, Share, Growth Analysis, By

Getting the Most From Milling Operations E MJ

A 42ft SAG mill was designed and built for Minas Congas mine in Peru, but never installed “The rise from 34 to 40ftdia SAG mills was quick, but then stalled,” Filidore explained “Today, we’re seeing a lot of 28ft ball mills Last month, we sold six 28ft ball mills and six 40ft SAG mills2021年12月27日 The aim of this study is to evaluate the effect that the size of grinding media exerts on ferronickel slag milling efficiency and energy savings A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizes In order to simulate the Effect of Grinding Media Size on Ferronickel Slag Ball Milling