Flotation Separation For copper Tailings

2021-02-20T10:02:14+00:00

Various flotation techniques for metal ions removal

2017年1月1日 Selective separation by flotation of molybdate oxyanions from impurities (P, As and Si): effect of initial molybdate concentrations Fig 5 given as an example from this area, shows copper ion flotation, where almost complete copper removal was obvious for 2018年6月15日 The copper grade in the concentrate of flotation tailings reached up to 065 mass% from the initial 035 mass%, and the copper recovery was achieved at 784% by Development of copper recovery process from flotation tailings 2022年5月6日 Flotation is a common mineral processing method used to upgrade copper sulfide ores; in this method, copper sulfide mineral particles are concentrated in froth, and associated gangue minerals are separated The Challenges and Prospects of Recovering Fine

Statistical investigation of flotation parameters for copper

2021年3月1日 A brief statistical analysis has shown that froth flotation is a reliable process to recover copper from flotation tailings • Collector dosage remains the main parameter 2018年1月10日 After flotation separation of the molybdenite from the other minerals (cleaner stage), the tailings were transferred to the cell of the Cu flotation system The Evaluation of the possibility of copper recovery from tailings 2023年1月19日 This study investigated the flocculation performances of a new generation UMA (Unique Molecular Architecture) technology polymer and conventional polymers in Improving Flocculation Performance of Copper Flotation Tailings

Metals Free FullText Processing Tests, Adjusted

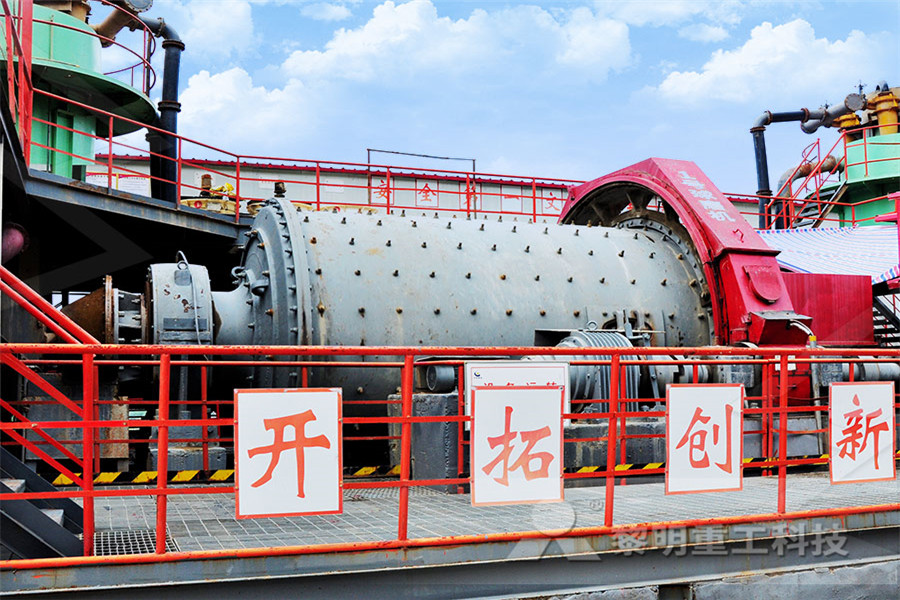

2021年1月6日 Standard cost models with capex and opex for flotation, leaching, and magnetic separation were adopted to the needs of tailings reprocessing A copper tailing (around 2 M t) that also contains 2019年1月21日 3The cleaned and grouped materials will be sent into flotation machine for recovery and enrichment 4After flotation separation, the ores will be processed by thickener and then dried by rotary dryer, Flotation Separation ProcessBAILING® Machinery2023年5月19日 Flotation separation process is a method which separates materials based on their different physical and chemical properties of the minerals It is not only used for sorting copper, zinc, lead, nickel, gold Flotation separation line,flotation separation

Separation of Iron and Rare Earths from LowIntensity

2023年10月30日 3 grade of magnetic separation tailings is 1198 % and 0013 %, respectively After the subsequent flotation and leaching process, rare earth, Sc 2O 3 2021年8月24日 The flotation tailings obtained from Bor Copper Mine contain pyrite (FeS2) and chalcopyrite (CuFeS2), these sulfide minerals are known to promote acid mine drainage (AMD) which poses a serious Metals Free FullText Copper Recovery and 2018年4月18日 Response surface methodology is used to optimize the leaching process for refractory flotation copper tailings The proportion of the refractory combination oxide copper (chrysocolla) is 6484% At present, Response Surface Methodology for Optimization

Chemical Composition Data of the Main Stages of

2022年2月16日 The mining industry has faced significant challenges to maintaining copper production technically, economically, and environmentally viable Some of the major limitations that must be 2022年8月19日 The flotation separation of common copperlead ore includes copper depression and lead flotation, or lead depression and copper flotation Inspection on the lead flotation tailings by an optical microscope shows that some chalcopyrite and a little bornite with poor flotability are still highly intergrown with galena, sphalerite and pyrite Mineralogy and Innovative Flash Flotation Separation of Cu 2022年3月19日 A comprehensive recovery process for the selective separation and enrichment of copper, zinc and iron minerals from a polymetallic ore was developed, which consisted of copper flotation, zinc flotation, and iron magnetic separation, and the adsorption mechanism of the copper collector Z200 (OisopropylNethyl thionocarbamate) was A Comprehensive Recovery Process for Selective Separation

Recycling Lepidolite from Tantalum–Niobium Mine Tailings

2020年12月2日 @article{Huang2020RecyclingLF, title={Recycling Lepidolite from Tantalum–Niobium Mine Tailings by a Combined Magnetic–Flotation Process Using a Novel Gemini Surfactant: From Tailings Dams to the “Bling” Raw Material of Lithium}, author={Zhiqiang Huang and Shiyong Zhang and Chen Cheng and Hongling Wang and 2022年4月27日 A number of studies were focused on the recovery of copper from its flotation tailings [18,22,152] Ramakokovhu et al investigated the beneficiation of copper tailings from the Konkola Copper mine in Nchanga, Zambia They studied the leaching characteristics of copper tailing before and after upgrading by using a Knelson gravity Minerals Free FullText Sustainable Use of Copper 2022年8月19日 Mineralogy and Innovative Flash Flotation Separation of CuPbZn Polymetallic Ore in Weak Acidic Pulp August 2022; Minerals 12(8):1041; Copper tailings 6218 229 1079 1777 7194(PDF) Mineralogy and Innovative Flash Flotation Separation

Metals Free FullText Copper Recovery and Reduction of

2021年8月24日 The flotation tailings obtained from Bor Copper Mine contain pyrite (FeS2) and chalcopyrite (CuFeS2), these sulfide minerals are known to promote acid mine drainage (AMD) which poses a serious threat to the environment and human health This study focuses on the treatment of mine tailings to convert the AMD supporting minerals to more 2019年8月14日 There is 0032% cobalt and 056% sulfur in the cobaltbearing V–Ti tailings in the Panxi Region, with the metal sulfide minerals mainly including FeS2, Fe1−xS, Co3S4, and (Fe,Co)S2, and the gangue minerals mainly including aluminosilicate minerals The flotation process was used to recover cobalt and sulfur in the cobaltbearing V–Ti tailings Processes Free FullText Recovering Cobalt and Sulfur in 2023年1月19日 Solid–liquid separation methods are applied to wastewater, which generally consists of fine particles and water; fine particles are settled in thickeners by the flocculation method and the Improving Flocculation Performance of Copper Flotation Tailings

Improving Flocculation Performance of Copper Flotation Tailings

2023年1月19日 The dewatering of tailings is one of the serious challenges that the mining and mineral processing industries have encountered internationally Solid–liquid separation methods are applied to wastewater, which generally consists of fine particles and water; fine particles are settled in thickeners by the flocculation method and the cleaned water is 2018年9月1日 Copper tailings constitute a large proportion of mine wastes Some of the copper tailings can be recycled to recover valuable minerals In this paper, a copper tailing was studied through the chemical analysis method, Xray diffraction and scanning electron microscopeenergy dispersive spectrum The selective flotation separation of pyrite Separation of chalcopyrite and pyrite from a copper tailing 2018年1月10日 Based on historical statistics of the Cu concentrations in separation tailings, the obtained Cu grade is in the range of 015–048%, which is lower than the global average of mined oregrade Cu (049%) a possible recovery of copper from tailings by flotation can be obtained Download : Download highres image (321KB)Evaluation of the possibility of copper recovery from tailings

Selective Process Route to Recover Magnetite from

2022年9月28日 This suggests, copper could be recovered from nonmagnetic cleaner tailings, which corresponds to 4% of copper fed in flotation tailings Considering the three steps, that is, screen classification, rougher, and cleaner magnetic separation, the total mass recovery is 302% (302% = 633% × 4769%) and Fe and SiO 2 recoveries were 3173% 2023年10月27日 Note: In most cases, the gravity separation can only be used as a coarse concentration method to coarsely concentrate lowgrade copper ore by discarding tailings before the flotation process It cannot be used as a copper separation method for obtaining the final copper concentrates Froth Flotation MethodCopper Ore Processing Plant Fote Machinery2021年6月5日 As ore grades constantly decline, more copper tailings, which still contain a considerable amount of unrecovered copper, are expected to be produced as a byproduct of froth flotation This research reveals the occurrence mechanism of copper minerals in typical copper sulfide tailings using quantitative mineral liberation analysis (MLA) integrated with Mineralogical characterization of copper sulfide tailings

Impact of Sodium Hexametaphosphate on the Flotation of

2021年5月8日 The depletion of ore deposits, the increasing demand for raw materials, the need to process lowgrade, complex and finely disseminated ores, and the reprocessing of tailings are challenges especially for froth flotation separation technologies Even though they are capable of handling relatively fine grain sizes, the flotation separation of very 2022年5月15日 The flotation reagents of butyl xanthate, isoamyl xanthate, and terpineol were used The copper concentrate and flotation tailings were subjected to a series of crushing, ore grinding, foam flotation, and concentration drying processes Iron concentrate (IC) and MST were obtained by further magnetic separation of crushed FTAn experimental comparison: Horizontal evaluation of 2023年5月16日 Commonly used physical separation processes include gravity concentration, magnetic separation, and/or flotation separation, and use jigs, flotation cells, and spirals separator equipment, In the case of copper mine tailings obtained by flotation, it is not mandatory to install geomembranetype geosynthetic systems on the entire SocioEnvironmental Risks Linked with Mine Tailings

Bioleaching of cobalt from sulfide mining tailings; a mini

2020年9月1日 1 Introduction Tailings are residual material streams generated in mining activities Regarding sulfide ore mines, tailings are typically produced in froth flotation process, where valuable sulfide minerals are selectively separated from nonvaluable gangue (Fuerstenau et al, 2007)After the separation, gangue minerals are disposed in 2021年1月5日 Tailings size distribution can be modified to greatly reduce surface storage area and the risk of catastrophic tailings dam failures Total flotation and backfill technology can even be used to store the tailings underground In Peru, dynamic neutralization and coagulation technology uses fine tailings as neutralizing and coagulating agents for acid Circular Economy in Tailings Management SpringerLink2022年10月17日 The aim of this study was to develop a comprehensive technology for the utilization of tailings from quartz veinhosted gold deposits We investigated the recovery potential and separation process Minerals Free FullText Comprehensive

Solvent extraction of Cu, Mo, V, and U from leach solutions of copper

2017年8月3日 Flotation tailings from copper production are deposits of copper and other valuable metals, such as Mo, V and U New hydrometallurgical technologies are more economical and open up new possibilities for metal recovery This work presents results of the study on the extraction of copper by mixed extractant consisting ptoluidine dissolved To this end, a summary of the overarching key results from froth flotation, magnetic separation, and gravity separation studies of the tailings and their implications are presented in this review Lutandula, MS; Maloba, B Recovery of cobalt and copper through reprocessing of tailings from flotation of oxidised ores J Environ Chem Eng Eng Free FullText Recovery of Rare Earth Elements 2021年4月27日 Sulfidic copper–lead–zinc tailings can pose a significant environmental threat, ranging from generation of acid mine drainage (AMD) to dam failures On the other hand, they can also be considered as lowgrade ore resources for zinc and copper provided that novel economically feasible metal extraction and metal recovery techniques are Recovery of Copper from Ammoniacal Leachates by Ion Flotation

Separation of chalcopyrite and pyrite from a copper tailing

2018年9月1日 For the copper tailings, the objective of the flotation is to detach the copper minerals from other sulfide minerals (usually pyrite) and the gangue minerals The main difficulty lies in the depression of pyrite, which conventionally proceeds in high pH conditions by using large amounts of lime (CaO)2022年1月1日 Mine tailings, the byproduct of mining and mineral processing, are increasingly mass produced as a result of increased demand for metals and minerals as well as the advancement in technology that allows for the exploitation of lowergrade ores Lower grades can increase the volume of tailings that may contain new gangue minerals that The Reprocessing and Revalorization of Critical Minerals in Mine Tailings2023年1月1日 Highsilicon iron ore tailing is typically regarded as abundant mining waste of little use; it occupies a vast area of land and is harmful to human health and the ecological environment Nevertheless, highsilicon iron ore tailing contains abundant quartz resource In this study, a superconducting high gradient magnetic separation (SHGMS) coupling Separation and purification of highpurity quartz from high

Mineralogical characterization of copper sulfide tailings

2021年6月5日 copper flotation tailings obtained from the mine have been reported to still contain 026wt% copper, which is larger than the economic grade (007%) for recovering single copper ele ings, which involves the liberation and separation of the interested mineral, is essential to improve the performance of flotation circuits [29] Mineral 2022年11月1日 The fresh copper oxide mineral surfaces exposed during crushing and grinding have a significant effect on subsequent flotation [23], [24], [25], [26]Many dangling bonds exist on fresh mineral surfaces because of destruction of the original lattice bonds, and the copper oxide mineral surface often shows strong polarity because of the Flotation of copper oxide minerals: A review ScienceDirect2021年8月15日 For instance, for the flotation separation of a ton of fine coppermolybdenum coflotation concentrate to be used in this investigation, which assays around 26% Cu and 035% Mo with 90–92% mass below 50 μm, a sodium sulfide (Na 2 S) consumption of 20–30 kg was practically required for depression of chalcopyrite against Pulsating HGMS for industrial separation of ScienceDirect

Present Situation of Comprehensive Utilization of Tailings

2019年12月8日 CENG C, WANG HJ, HU WT, et al Recovery of iron and copper from copper tailings by coalbased direct reduction and magnetic separation[J] Journal of Iron and Steel Research, International, 2017, 24(10):9919972019年9月1日 The pyrite grade in the fresh tailing sample and in the flotation product was determined indirectly from the content sulfur, copper and iron Calculations carried out considering the elemental chemical composition presented in Table 1 and the mineralogical species that contained sulfur, identified by the XRD analysis, allowed to determine that Recovery of pyrite from copper tailings by flotation2022年12月1日 The slag tailings contained 026 % copper, which was higher than that of some copper mines being mined, indicating that measures were needed to reduce the copper grade in tailings The mineralogical characteristics of CSS and its flotation products should be profoundly studied for improving the arsenic recovery of concentrate and Mineralogical characteristics of copper smelting slag

Potentially Exploitable Reprocessing Routes for Recovering Copper

2021年1月4日 Abstract This research aimed at recovering metals retained in the tailings from the flotation of copper (Cu) and cobalt (Co) ores conducted at the New Concentrator in Kipushi (NCK) Metals retention in the tailings (073% Cu and 037% Co) increased due to the removal of the gravity separation section from the processing circuit together with 2021年3月1日 4Froth flotation is an option of choice in recovering copper from flotation tailings regardless of its nature An insight analysis of several other parameters and mechanistic details both on lab and pilot scale can be built upon the conclusion of this work The critical role of pulp density on flotation separation of nickelcopper sulfide Statistical investigation of flotation parameters for copper 2020年10月12日 Typically, the separation and recovery of chalcopyrite (CuFeS 2) and molybdenite (MoS 2), the major Cu and Mo minerals, respectively, in PCDs are achieved by twostep flotation involving (1) bulk (PDF) A Review of Recent Advances in Depression Techniques

An experimental comparison: Horizontal evaluation of

2022年5月15日 Usually, the reductionmagnetic separation method (Guo et al, 2018a, Li et al, 2019) was used to extract iron from flotation tailings At present, flotation and smelting reduction (Rajcevic and Opie, 1982) are the most common methods for treating copper smelting slag, which are suitable for flash smelting, oxygen bottomblown smelting, and 2016年5月16日 After the rougher flotation concentrate is reground it is cleaned twice in additional “FreeFlow” Flotation Machines with the recleaned concentrate going to final concentrate filtration or, as the metallurgy dictates, to a coppermoly separation circuit The tailings or middlings from the flotation cleaning circuit can either go to a Copper Flotation 911 Metallurgist2021年8月24日 The flotation tailings obtained from Bor Copper Mine contain pyrite (FeS2) and chalcopyrite (CuFeS2), these sulfide minerals are known to promote acid mine drainage (AMD) which poses a serious Metals Free FullText Copper Recovery and

Response Surface Methodology for Optimization

2018年4月18日 Response surface methodology is used to optimize the leaching process for refractory flotation copper tailings The proportion of the refractory combination oxide copper (chrysocolla) is 6484% At present, 2022年2月16日 The mining industry has faced significant challenges to maintaining copper production technically, economically, and environmentally viable Some of the major limitations that must be Chemical Composition Data of the Main Stages of 2022年8月19日 The flotation separation of common copperlead ore includes copper depression and lead flotation, or lead depression and copper flotation Inspection on the lead flotation tailings by an optical microscope shows that some chalcopyrite and a little bornite with poor flotability are still highly intergrown with galena, sphalerite and pyrite Mineralogy and Innovative Flash Flotation Separation of Cu

A Comprehensive Recovery Process for Selective Separation

2022年3月19日 A comprehensive recovery process for the selective separation and enrichment of copper, zinc and iron minerals from a polymetallic ore was developed, which consisted of copper flotation, zinc flotation, and iron magnetic separation, and the adsorption mechanism of the copper collector Z200 (OisopropylNethyl thionocarbamate) was 2020年12月2日 @article{Huang2020RecyclingLF, title={Recycling Lepidolite from Tantalum–Niobium Mine Tailings by a Combined Magnetic–Flotation Process Using a Novel Gemini Surfactant: From Tailings Dams to the “Bling” Raw Material of Lithium}, author={Zhiqiang Huang and Shiyong Zhang and Chen Cheng and Hongling Wang and Recycling Lepidolite from Tantalum–Niobium Mine Tailings 2022年4月27日 A number of studies were focused on the recovery of copper from its flotation tailings [18,22,152] Ramakokovhu et al investigated the beneficiation of copper tailings from the Konkola Copper mine in Nchanga, Zambia They studied the leaching characteristics of copper tailing before and after upgrading by using a Knelson gravity Minerals Free FullText Sustainable Use of Copper

(PDF) Mineralogy and Innovative Flash Flotation Separation

2022年8月19日 Mineralogy and Innovative Flash Flotation Separation of CuPbZn Polymetallic Ore in Weak Acidic Pulp August 2022; Minerals 12(8):1041; Copper tailings 6218 229 1079 1777 71942021年8月24日 The flotation tailings obtained from Bor Copper Mine contain pyrite (FeS2) and chalcopyrite (CuFeS2), these sulfide minerals are known to promote acid mine drainage (AMD) which poses a serious threat to the environment and human health This study focuses on the treatment of mine tailings to convert the AMD supporting minerals to more Metals Free FullText Copper Recovery and Reduction of 2019年8月14日 There is 0032% cobalt and 056% sulfur in the cobaltbearing V–Ti tailings in the Panxi Region, with the metal sulfide minerals mainly including FeS2, Fe1−xS, Co3S4, and (Fe,Co)S2, and the gangue minerals mainly including aluminosilicate minerals The flotation process was used to recover cobalt and sulfur in the cobaltbearing V–Ti tailings Processes Free FullText Recovering Cobalt and Sulfur in