install a secondary crusher

2021-04-21T01:04:55+00:00

The Complete Guide to Primary Crushing,

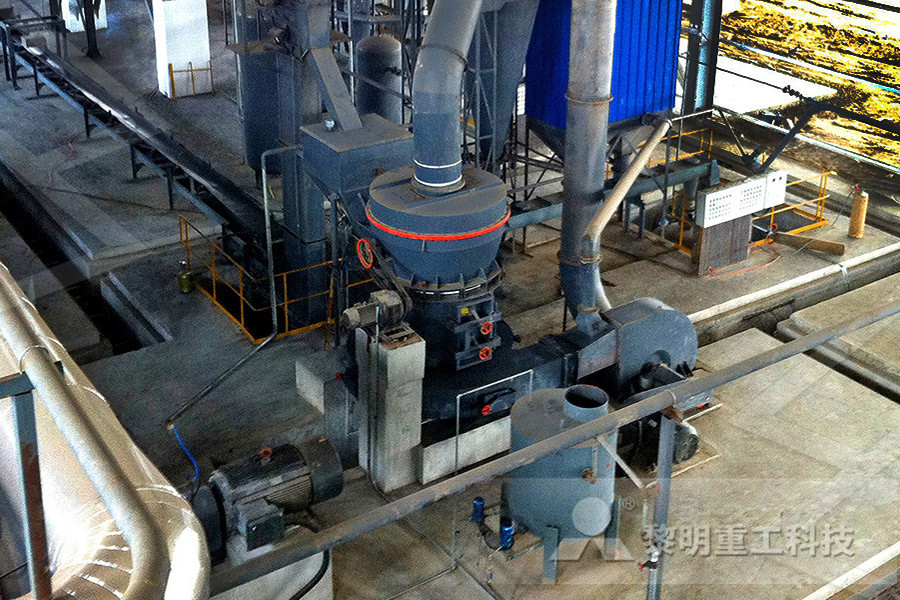

2023年2月28日 The working principle of secondary crushers varies depending on the type of crusher, but generally, they work by applying pressure to the material through compression or impact Cone crushers 2023年1月15日 Installing a secondary crusher can be a complex and timeconsuming process, but it can be done by following these steps: Prepare the site: Clear the area How to install a secondary crusher? LinkedInContribute to redmik40/ development by creating an account on GitHub/ secondary crusher installmd at main redmik40/

Secondary crusher Article about secondary crusher by The

The total $55million project costs include $10 million in mill upgrades to install a secondary crusher at their 15,000tonnesperday processing mill Expanding markets predicted for 2016年2月28日 The term “ secondary crushing ” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which Secondary Crushing Equipment 911 Metallurgist2018年12月26日 The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary (second), tertiary (third) Construction, Working and Maintenance of Crushers for

Definition of secondary crusher mindat

Definition of secondary crusher Crushing and pulverizing machines next in line after the primary crushing to further reduce the particle size of shale or other rock All types of jaw How to set up a stone crusher plant From feeding large material into the plant to primary secondary crushing and screening each phase of the stone crushing process needs the Stone Crusher Plant Setup Machinery Partner The XL2000 cone crusher is intended for secondary or tertiary applications and does not replace the need for a primary gyratory or jaw crusher However, the XL2000 To Install Secondary Crusher

Crushers All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of 2021年7月19日 macOS uses similar steps to Windows 10 to connect or pair Skullcandy wireless headphones Open the Apple menu on your Macbook (located in the topleft corner) and select System Preferences How to Pair Skullcandy Headphones LifewireThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 AMIT 135: Lesson 5 Crushing – Mining Mill

Impact Crusher Blow Bars Information Tips Frontline

2020年6月10日 Impact crusher blow bars play an important role in crushing applications Typically manufactured into large, thick slabs of highstrength alloys or hybrid composites, they can also be referred to as hammers, impact hammers, or breaker bars Regardless of the name, they all serve the same purpose of fracturing up materials such as concrete 2020年9月16日 A jaw crusher is a type of crusher comprised of two jaw plates One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a Five Types of Crusher in the Mineral Processing LinkedIn2021年6月24日 secondary, tertiary or quarternary crushing applications High performance technology Impact crushers – primary and secondary machines for soft and mediumhard materials High reduction ratios Can eliminate need for a tertiary crushing stage Spare and wear parts – genuine parts always close to you, no matter where you are located worldwideCrushing and Screening Handbook AusIMM

HP Series cone crushers – High performance

2022年1月21日 secondary stage because it significantly reduces the risk of blockage to ensure an unrestricted flow of feed material into the crusher cavity Proven and predictable production Ease of use is builtin to the HP Series and the design makes maintenance tasks quick, convenient and safe The crusher is easy to open, it has a very effective tramp ® C80™ jaw crusher is optimal for smallerscale operations Even though ® C80™ jaw crusher is commonly used as a primary crusher, it also performs well in other roles, depending on the processed material and application ® C80™ jaw crusher is the smallest model in the popular ® C Series™ jaw crushers ® C80™ jaw crusher 2020年6月3日 For businesses that process large pieces of raw material, cone crushers are used as a secondary or tertiary crusher The Benefits of Cone Crushers Cone crushers offer a bunch of benefits that are helpful for practically every industry that relies on this equipment Many manufacturers turn to a cone crusher because it provides:A Detailed Overview of Cone Crushers and What You Need

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by:MMD Sizers are tailored to each application to provide the best operation and cater to all your requirements 400mm Overall Height The 200 and 350 Series Sizers are our smallest machines we produce They are designed for processing lower tonnages and producing smaller product sizes Tooth configurations vary depending on the material type Sizers MMD2017年4月24日 A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building application Most rock crushers have a hopper at the top a container which holds the How Does a Rock Crusher Work? Sciencing

Development of Mobile Impact Crusher BR480RG

2021年6月30日 secondary crusher or granulator Since the impact crusher is 15 to 2 times higher in crushing ratio than the jaw crusher, it is suitable to produce aggregates of comparatively small particle size The BR480RG is equipped with a feeder and a conveyor appropriate to the crusher width to allow for efficient crushing work2023年11月3日 Why Install a Cone Crusher Another point for consideration is that the 10 Ft, cone crusher is a secondary crusher and normally would be fed with the product of a gyratory crusher Since the 10 Ft can accept a larger feed than a 7 Ft crusher, it is possible to increase the open side setting of a gyratory crusher, thereby, allowing a Symons Cone Crusher 911 Metallurgist2016年7月12日 The oversize from the secondary screens is crushed in a 5½ft Symons short head crusher set at 3/8 in, and the oversize from the tertiary screens crushed in a set of 78 by 20in rolls set at 3/16 in Both machines are closedcircuited with the secondary screen, and in this respect the flow sheet differs from the fourstage crushing at Crushing Screening Plant 911 Metallurgist

Types of Crushers: What You Need to Know Machinery

The average input size for a secondary crusher ranges from 13" to 4" during this stage Secondary crushing is especially important for making graded material that is going on to be used on government projects For example crushed material for road base and fill The main kinds of crushing machines for secondary processing are discussed below2020年4月15日 date ensure a strong and reliable crusher design The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handle increasingly hard ores and remote site locations Performance An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic designCrushing Systems 2021年7月26日 Secondary Plants 50005 CVSS; 120025 OCSS; Specialty Systems The MaxRap® System; Jaw/Impactor System; the inline or cross belt magnet is a valuable crusher component for separating rebar and other metal contaminates quickly and automatically from the concrete being crushed and recycled Beyond helping to generate Magnets and Crushing: Inline or Cross Belt Eagle Crusher

Crushers Selection Guide: Types, Features, Applications

1 天前 These types include: Cone or gyratory crushers insert feed via a coneshape bowl and crush it with a spinning or gyrating head HPGR (high pressure grinding rollers), roll/roller crushers, or mineral sizers use two large rollers or a roller and a flat surface The rolls can be serrated, toothed, or smooth Vertical impactors use the weight and ® C120™ jaw crusher has a range of bolton options, including an onboard motor base and guarding for the flywheel and drives, made from specially developed composite materials The unit is simple to install as a single crusher or as a complete module in a new or existing plant ® C120™ jaw crusher is mounted without bolts ® C120™ jaw crusher 2023年1月20日 secondary stage because it significantly reduces the risk of blockage to ensure an unrestricted flow of feed material into the crusher cavity Proven and predictable production Ease of use is builtin to the HP Series and the design makes maintenance tasks quick, convenient and safe The crusher is easy to open, it has a very effective tramp HP Series cone crushers – High performance

Primary and Secondary Crushing: Understanding

2023年2月28日 The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher The secondary crusher has a size reduction ratio ranging from 2023年11月3日 2Year / 6,000 Hour Superior crushers come backed by a rocksolid 2year / 6,000hour warranty against manufacturer defects Superior manufactures fifteen Americanmade models, which are gaining a strong reputation Connect with one of our crushing experts and find the right machineCrushing Equipment Superior Industries US Manufacturer2016年2月28日 The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its feedThe term should not be used, as it sometimes is, to designate Secondary Crushing Equipment 911 Metallurgist

Industrial Solutions Impact crushers ThyssenKrupp

2022年11月21日 Stationary singleshaft impact crusher fed by two apron feeders at Cementos Progreso SA, Guatemala Type PB 200/250 CR Throughput rate 1,100 t/h Mobile impact crusher with hydraulic walking mechanism at Martin Marietta, Texas, USA Type PB 250/300 CR Throughput rate 4,500/2,700 t/h Mobile wheelmounted impact crusher2016年2月24日 gyratories expected soon, as well as secondary and tertiary machines of up to 3,000 mm (120 in) • Rising energy costs are causing owners to increase the integration of mine and mill design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed Crushing Plant Design and Layout Considerations 911 2014年10月27日 The way how a can crusher works is pretty simple Aluminum can crusher consists from a frame, handle with soft grip at the end, hinges, compressing plate and metal bolts that hold all mechanism together These parts can be made from different materials, depending on the type of can crusher Cheaper can crushers are made from plastic partsWhat a Can Crusher Is and How it works ? DoRecycling

Softstarters ABB

Softstarters ABB's softstarter is an electrical device connected between the main power and the motor The softstarters increase a motor's lifetime by protecting it from electrical stresses With many builtin motor protection features, your motor is safe in its hands The softstarter is also easy to learn and setup2023年2月28日 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes Each stage uses different types of crushers and has distinct advantages and disadvantages This article provides a comprehensive guide to primary, secondary, and tertiary crushingThe Complete Guide to Primary Crushing, Secondary 2023年4月10日 The first step in installing a stone crusher is preparing the site for the installation The site should be cleared of any vegetation, rocks, or debris The area should be leveled, and any slopes How to install the stone crusher? LinkedIn

HP Series cone crushers – High performance

2023年1月20日 secondary stage because it significantly reduces the risk of blockage to ensure an unrestricted flow of feed material into the crusher cavity Proven and predictable production Ease of use is builtin to the HP Series and the design makes maintenance tasks quick, convenient and safe The crusher is easy to open, it has a very effective tramp 2021年1月10日 An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size Used in a wide variety of applications, including aggregate crushing, What Is an Impact Crusher and What Can It Do for You?Some interparticle crushing (rock on rock crushing) also occurs inside the chamber They are designed for secondary, tertiary and quaternary crushing of primary crushed ore and aggregates At Weir, we offer both the liveshaft and fixedshaft ("pedestal") cone crusher designs to service the diverse needs of our global mining and aggregate Trio® Crushing Equipment Weir

Secondary Tertiary Crushing Circuits 911 Metallurgist

2015年7月24日 The coarse material will be crushed by the secondary crusher The fines will be taken out of the circuit Once the secondary has finished with the ore it will be reclassified by a second set of screens with the oversize going to the tertiary crusher The discharge of the tertiary is reintroduced to the screen deck to ensure that the ore size is Rock Crusher Types Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business We also customdesign topperforming crusher systems from the industry's best equipment that will work hard to make finished aggregate products like crushed stone, geosynthetic aggregates, sand and gravel, fertilizer, lime, Rock Crushing Equipment Rock Crushers Kemper EquipmentThe stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners They all work together to crush stone as efficiently as possible Conveyors connect everything, moving the crushed material from one station to the next Stone crusher plant equipment is divided into two categories:Stone Crusher Plant Setup Machinery Partner

what is a primary and secondary crusher? LinkedIn

Published Feb 10, 2023 + Follow Primary crushers and secondary crushers are used in the mining and quarrying industry to crush rocks and aggregate, respectively A primary crusher is a heavy 2023年5月26日 A minimum area should be mandated by SPCB for establishment of a crusher, which can accommodate crusher green area, storage area and vehicular parking section SPCB should work with stone crusher associations for the construction of metalled road throughout the crusher zones; Point 1: accepted and included Provision of timing CPCB’s new guidelines for India’s stone crusher sector a 2023年2月28日 The primary crusher is used to reduce the size of the initial rocks, while the secondary crusher further breaks down the smaller pieces into finer materials Purpose and Benefits of Using Primary and Secondary Crushers The primary and secondary crushers play a crucial role in the crushing process They help to break down large rocks and Primary vs Secondary Crushers: Understanding the

Crushers All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of 2021年7月19日 macOS uses similar steps to Windows 10 to connect or pair Skullcandy wireless headphones Open the Apple menu on your Macbook (located in the topleft corner) and select System Preferences How to Pair Skullcandy Headphones LifewireThe purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit The ratio of reduction through a primary crusher can be up to about 8:1 AMIT 135: Lesson 5 Crushing – Mining Mill

Impact Crusher Blow Bars Information Tips Frontline

2020年6月10日 Impact crusher blow bars play an important role in crushing applications Typically manufactured into large, thick slabs of highstrength alloys or hybrid composites, they can also be referred to as hammers, impact hammers, or breaker bars Regardless of the name, they all serve the same purpose of fracturing up materials such as concrete 2020年9月16日 A jaw crusher is a type of crusher comprised of two jaw plates One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a Five Types of Crusher in the Mineral Processing LinkedIn2021年6月24日 secondary, tertiary or quarternary crushing applications High performance technology Impact crushers – primary and secondary machines for soft and mediumhard materials High reduction ratios Can eliminate need for a tertiary crushing stage Spare and wear parts – genuine parts always close to you, no matter where you are located worldwideCrushing and Screening Handbook AusIMM

HP Series cone crushers – High performance

2022年1月21日 secondary stage because it significantly reduces the risk of blockage to ensure an unrestricted flow of feed material into the crusher cavity Proven and predictable production Ease of use is builtin to the HP Series and the design makes maintenance tasks quick, convenient and safe The crusher is easy to open, it has a very effective tramp ® C80™ jaw crusher is optimal for smallerscale operations Even though ® C80™ jaw crusher is commonly used as a primary crusher, it also performs well in other roles, depending on the processed material and application ® C80™ jaw crusher is the smallest model in the popular ® C Series™ jaw crushers ® C80™ jaw crusher 2020年6月3日 For businesses that process large pieces of raw material, cone crushers are used as a secondary or tertiary crusher The Benefits of Cone Crushers Cone crushers offer a bunch of benefits that are helpful for practically every industry that relies on this equipment Many manufacturers turn to a cone crusher because it provides:A Detailed Overview of Cone Crushers and What You Need

Gyratory Crusher (Gyratory Crushers Explained) saVRee

A primary crusher is designed to receive runonmine (ROM) rocks directly from the mines Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about onetenth of its original size Gyratory crushers are always installed vertically orientated A gyratory crusher’s size is classified by: